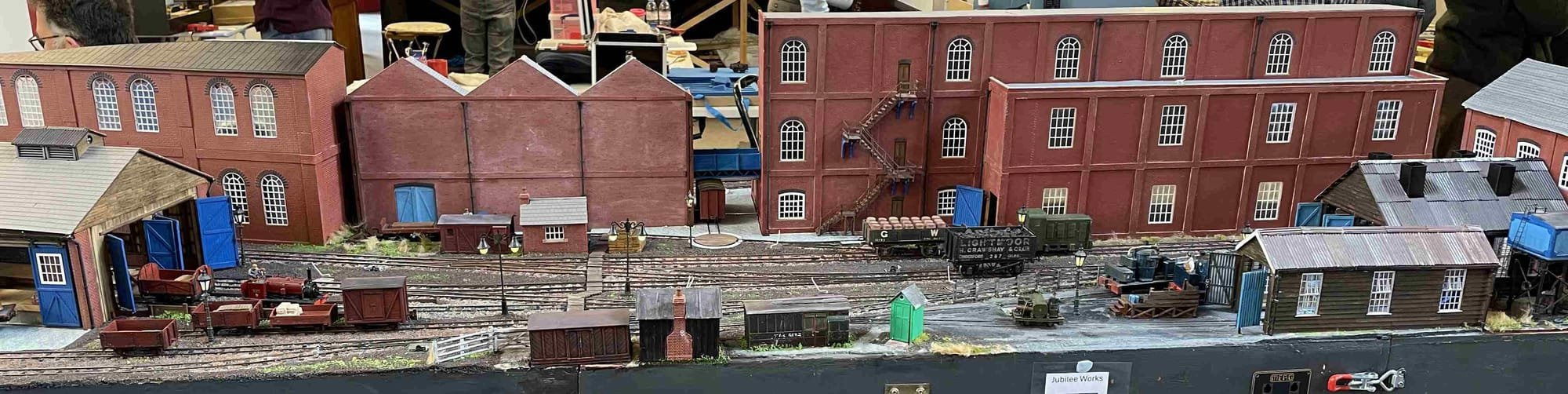

Jubilee Works

A Model Railway in 1/43 (O) Scale

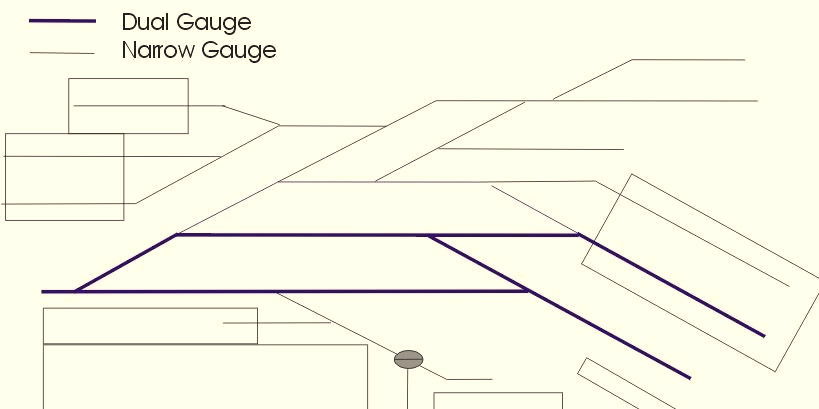

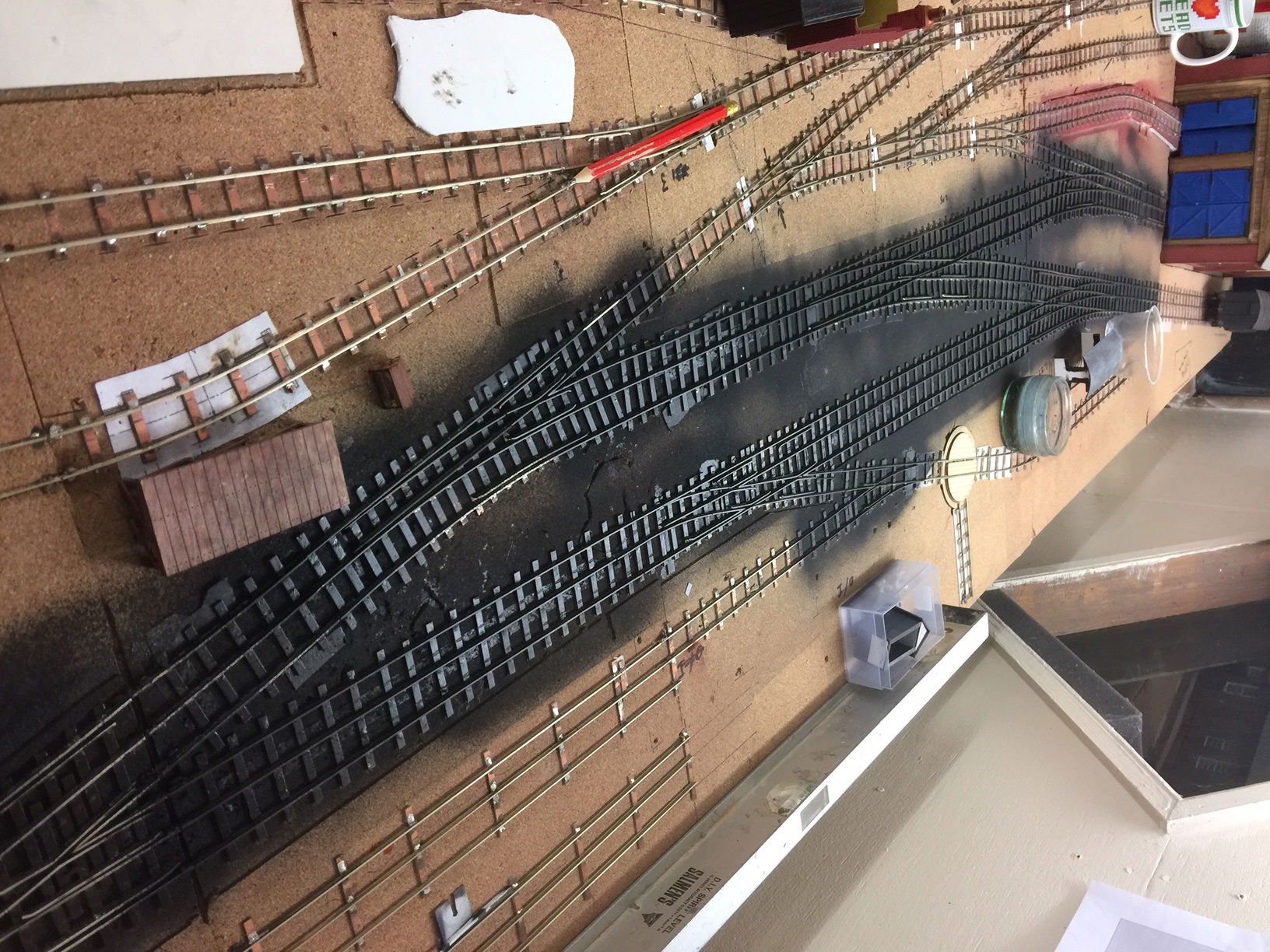

The works has is own extensive internal narrow gauge system and standard gauge feeder.

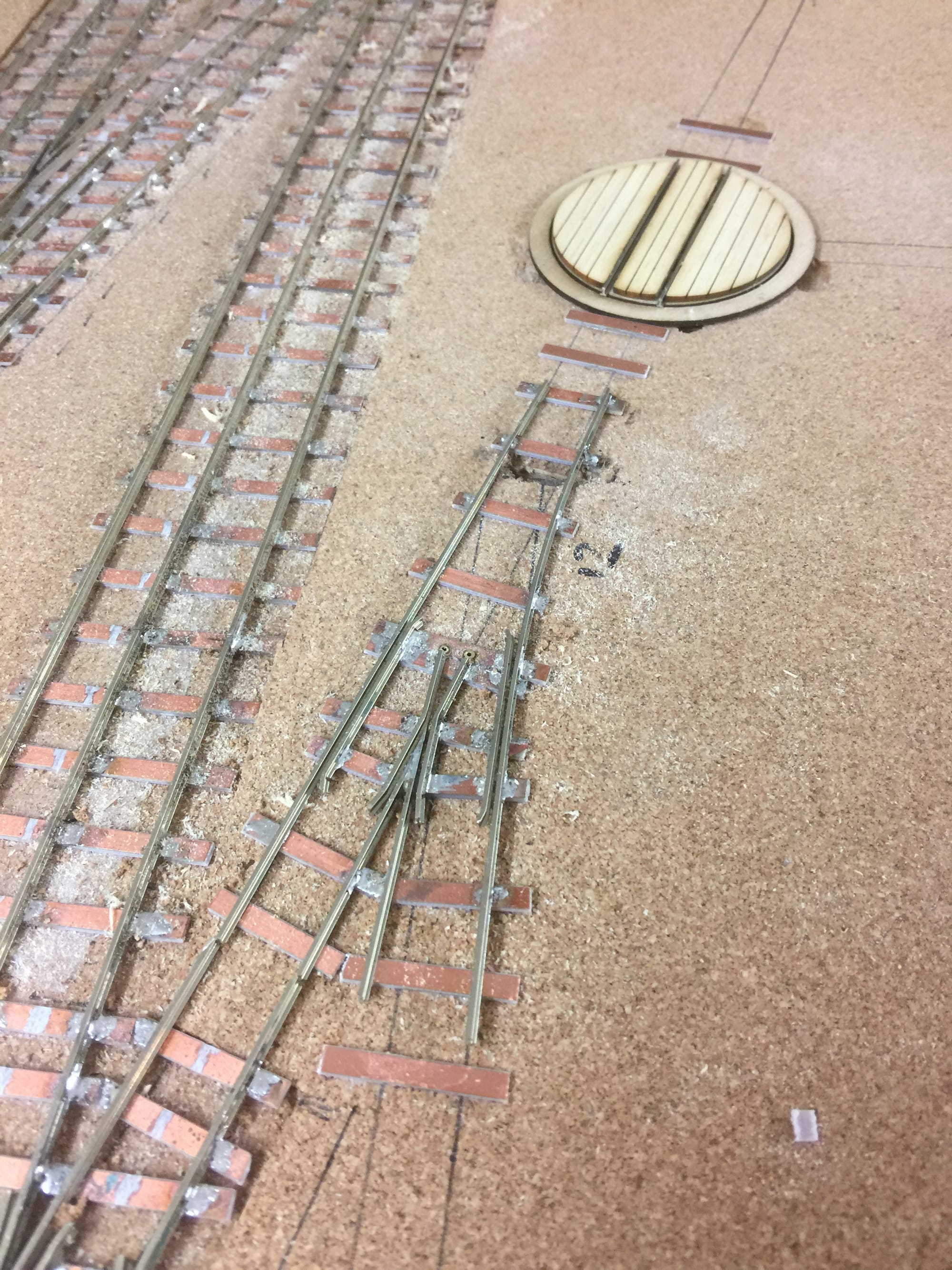

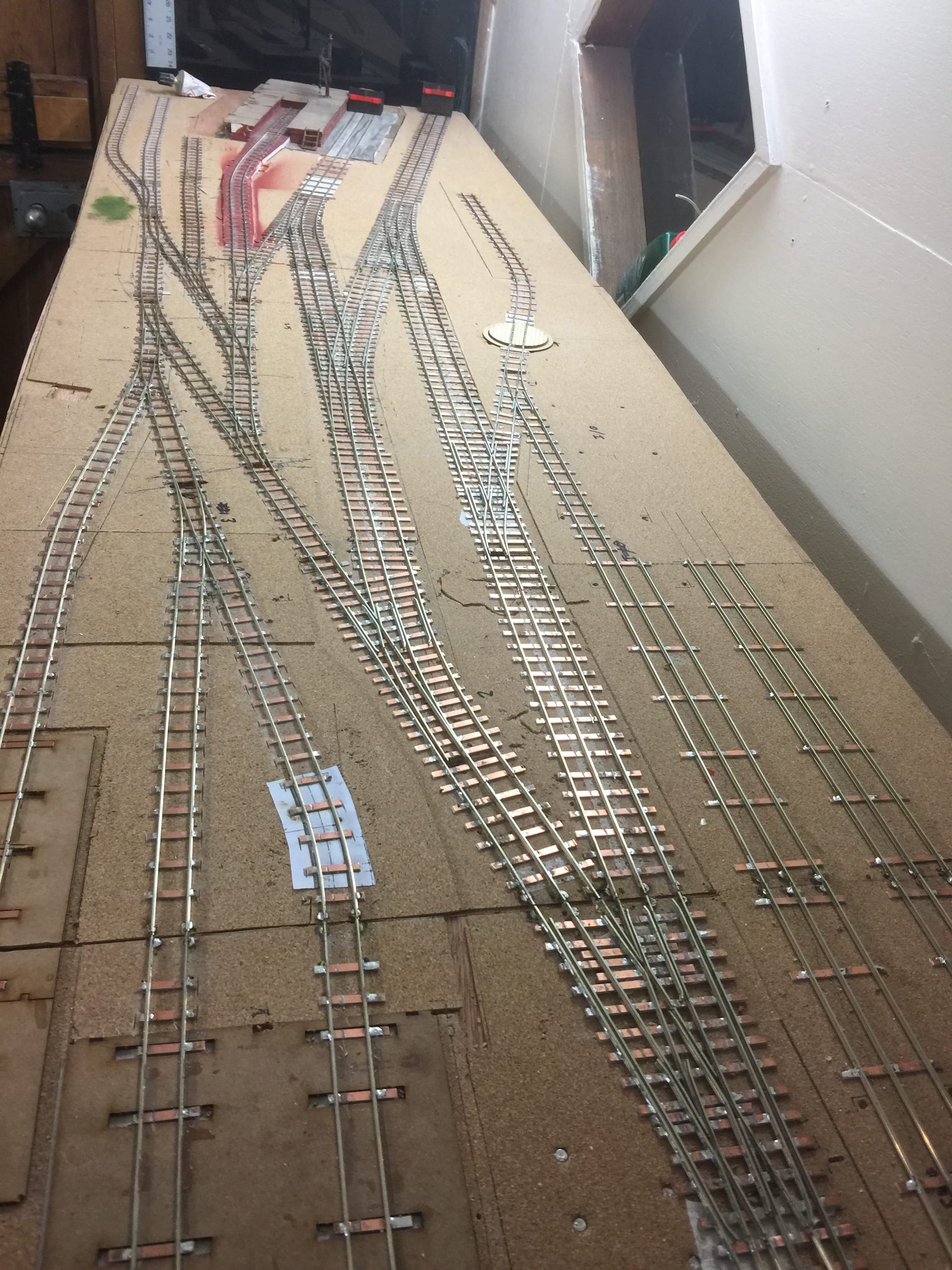

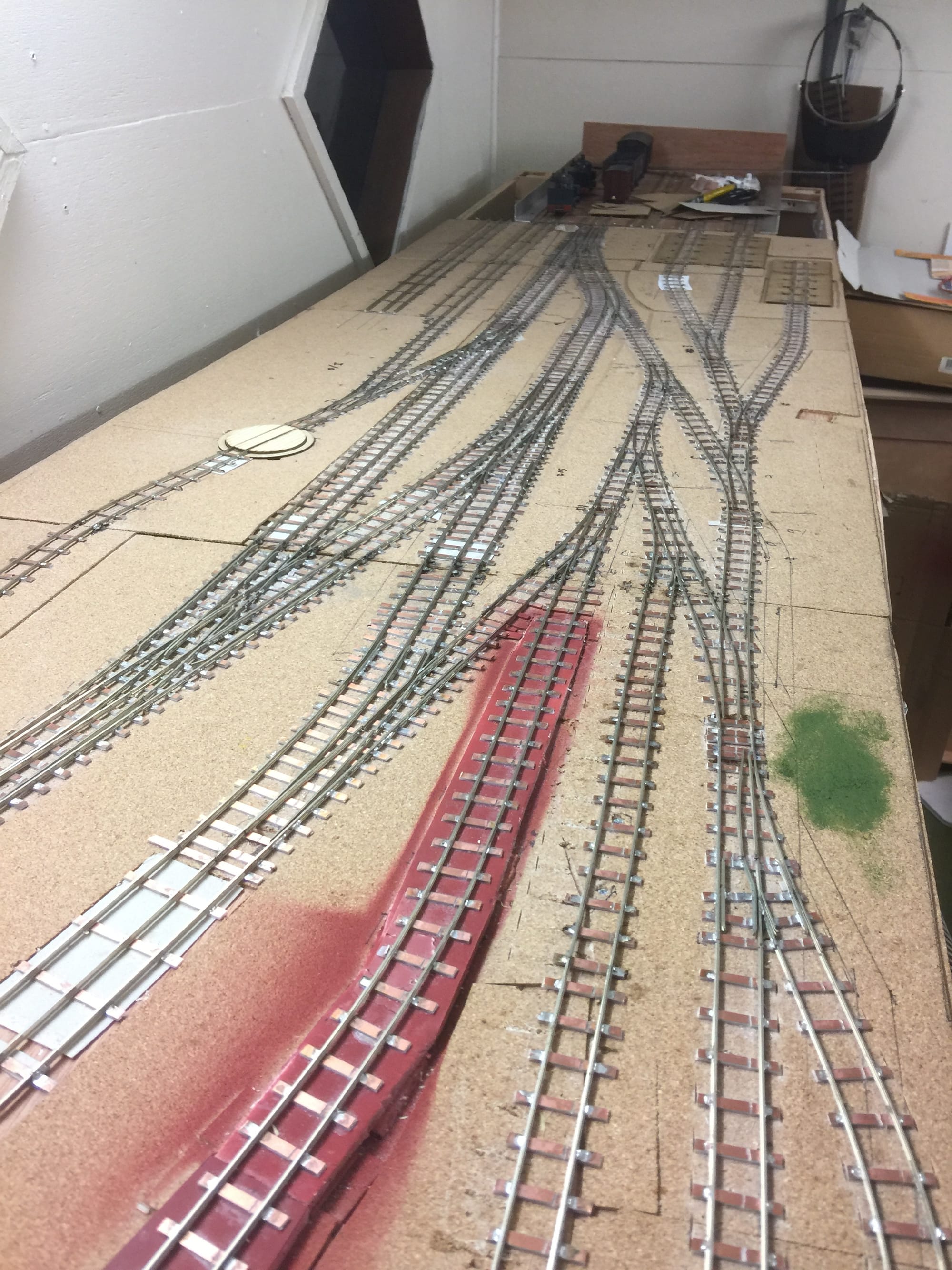

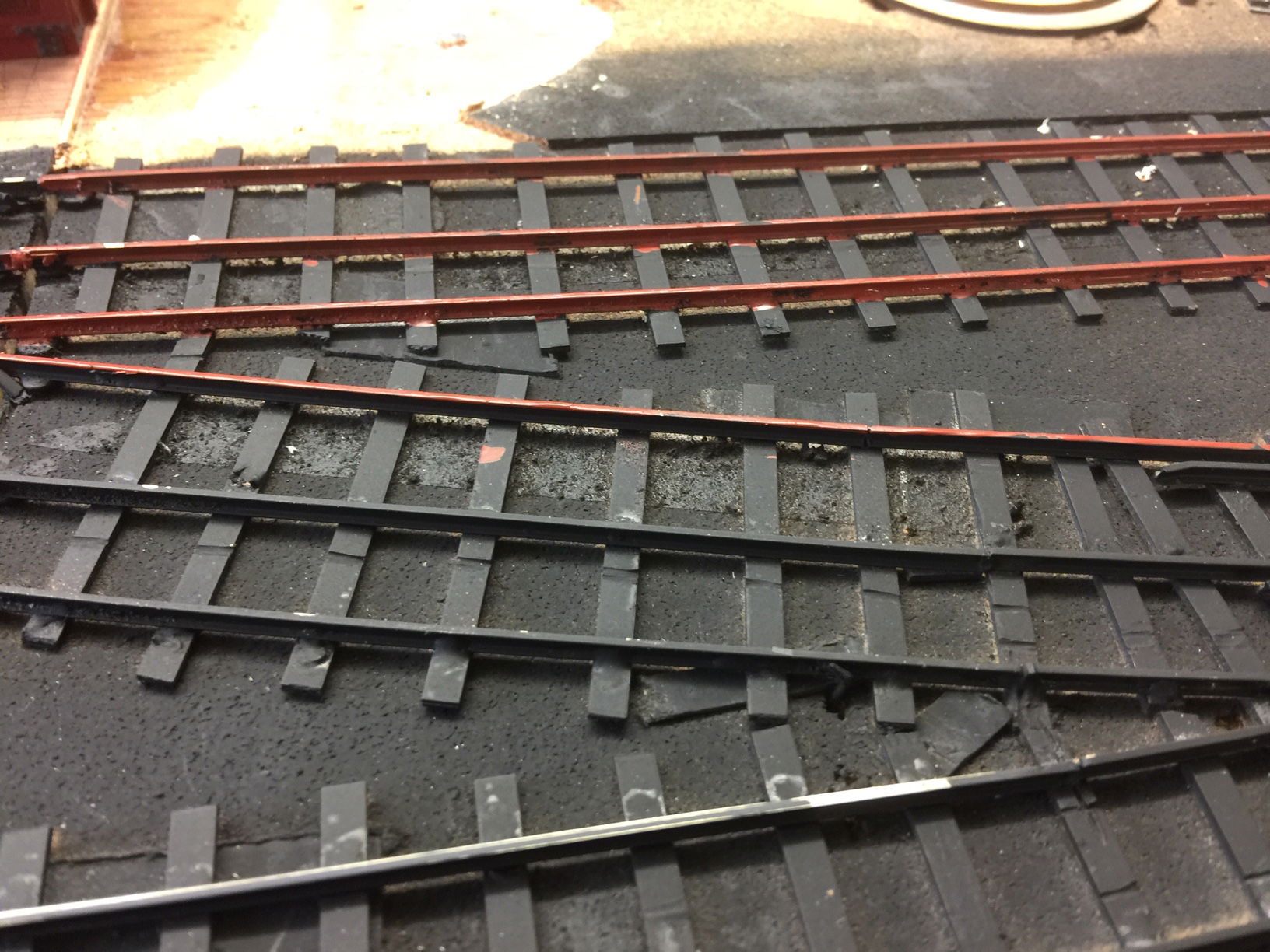

In the area covered by the model there is, unusally for the UK, an area of dual gauge trackwork.

I was inspired by such practices in Euope and spurred on when several opinions were that it could not be done in model form.

This website is intended to document the building of Jubilee Works. Both progress and picture taking have been a bit erratic, Pictures are dated for when taken which may, or may not, be when the work was done.

Locos

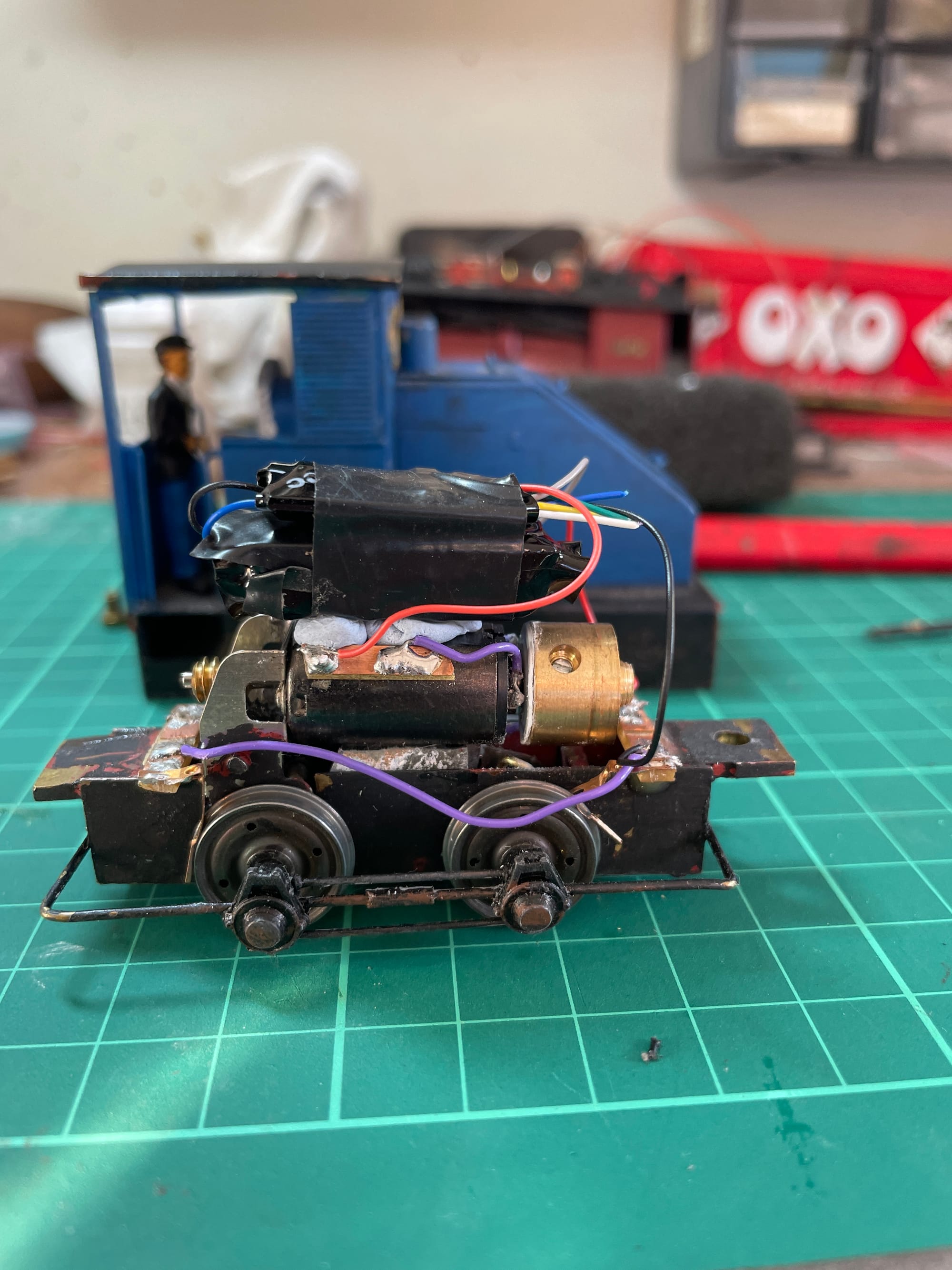

The Blue Simplex

Nos 1

My first O14 locomotive, this straight frame simplex was purchased from wrightlines, originally a Roy C link kit this ran for many years on the wrightlines chassis. Controllability was always an issue so eventually a KB Scale chassis was used instead. For Jubilee works fitted with a DCC decoder and keep alive unit.

'Alex'

Nos 2

An alexander chaplin from the smallbrook studio Kit it runs on my fist scratchbuilt chassis. This uses a Mashima 10 series motor with a high level gearbox all sitting below the footplate. The gap in the front of the boiler (for the motor on the intended chassis) has been filled in and detail added below the cylinders. The DCC conversion was easy the inside of the boiler being free for the decoder and keep alive.

Dick Kerr

Nos 3

The body was from the worsley works scratch aid etchings originally on a scratch built chassis using my favoured Mashima / high level drive train. This always lacked adhesion, drive only being on 1 axle, limiting the loads the engine could be used for. It was also unexplainably noisy. At one exhibition I was asked which sound chip I had used, the loco was still DC at the time ! It now has the Loco’s n stuff chassis and dcc with keep alive.

The Green Simplx

Nos 4

From the Nigel Lawton kit for a bow frame simplex. I never got the powered cooling fan working satisfactorily and have now removed the motor / gearbox for it to make space for a decoder and keep alive

'Bee' and 'Charlie'

Nos 5 and Nos 6

Two More Alexander chaplins. I decided a ‘class’ of loco’s would be good on my previous layout and got set up for mass production. The chassis are from a custom etch I had made with Mashima 14 series motor vertical in the boiler and a large flywheel. Bodies are smallbrook studio as per nos 2 ‘Alex’. It was only when 5 & 6 entered service that nameplates were required, previously Alex was referred to as"the alex" (Alexander Chaplin) with 2 siblings it formally became ‘Alex’, After A comes ‘ ‘Bee’ and Chapin C it just had to be ‘Charlie’. With the larger motors and flywheels there was limited space for dcc. I got the decoders in the boiler alongside the motor but no keep alives are fitted.

Kerr Stuart

Nos 7

The larger 6 wheeled version is better known. Only 4 of the smaller units being produced. A Worsley Works scratch aid kit on a scratch built chassis with mashima motor and high level drive train, quad driver I think. Now fitted with DCC and keep alive until recently the loco with the largest loading gauge at Jubilee works.

Lister

Nos 8

From the KB scale kit, This has an etched chassis, unlike the milled chassis provided by Roy C link. This proved useful when looking for space for the DCC decoder which was still challenging. No keep alive, what a shock !

'Puff'

Nos 9

Quarry Hunslet from a kit by Mercian models a 14 series Mashima motor, in the saddle tank, drives via a tall High Level gearbox. DCC and keep alive are fitted.

Muir Hill Fordson

Nos 10

The body was from a nonneminstre models kit and was originally on the wrightines chassis removed from nos 1. As this still retained is 2 speeds (nothing and supersonic) a Locos n stuff universal bogie was substituted. Another challenge when converting to DCC a decoder has been hidden but Keep alive was again impractical

Baldwin Gas Mechanical

Nos 11

Built from a Nigel Sawyer Kit with a mashima motor. The provided gearbox has been replaced with a High Level unit as I wanted a grub screw secured pinion rather than a push fit. Initially lacking traction some 30g of roofing lead was concealed under the bonnet and all is now well. Built with DCC and Keep alive.

Stanley

Nos 12

In the early 90’s I was a regular driver of Stanley on the HBLR a pioneering O/14 layout. He was Given to me by one of it’s builders as he did not expect to use his O/14 stock again. A Baldwin 10-12-D with a Wrightlines Body on a scratch built fully compensated chassis. I have converted to DCC (no keep alive) Route availability restricted as outside the original loading gauge.

The bug

Nos 14

Another HBLR locomotive freelance so perhaps a Jubilee Works apprentice project? A Brass body on a Wrightlines chassis a gentle touch on the throttle is needed. Again DCC fitted for Jubilee works.

'Sir Fletton'

Nos 15

A white metal body of a Glyn Valley Hunslet again ex HBLR. A visit to the works was required on arrival as the tyres of the wheels kept coming off. As part of conversion to DCC, with Keep alive, a more modern motor was substituted as the current draw on the original was excessive. Route availability restricted now the engine requiring the largest loading gauge. For those not aware a Fletton is a type of brick to which there is some resemblance.

'Primus'

Nos 16

The Final HBLR locomotive to join the Jubilee works stud. A more modern motor was fitted as part of the DCC conversion. A scratch built brass body, I think he looks a bit fletcher Jennings, but not of a known prototype. Route availability restricted as outside the original loading gauge.

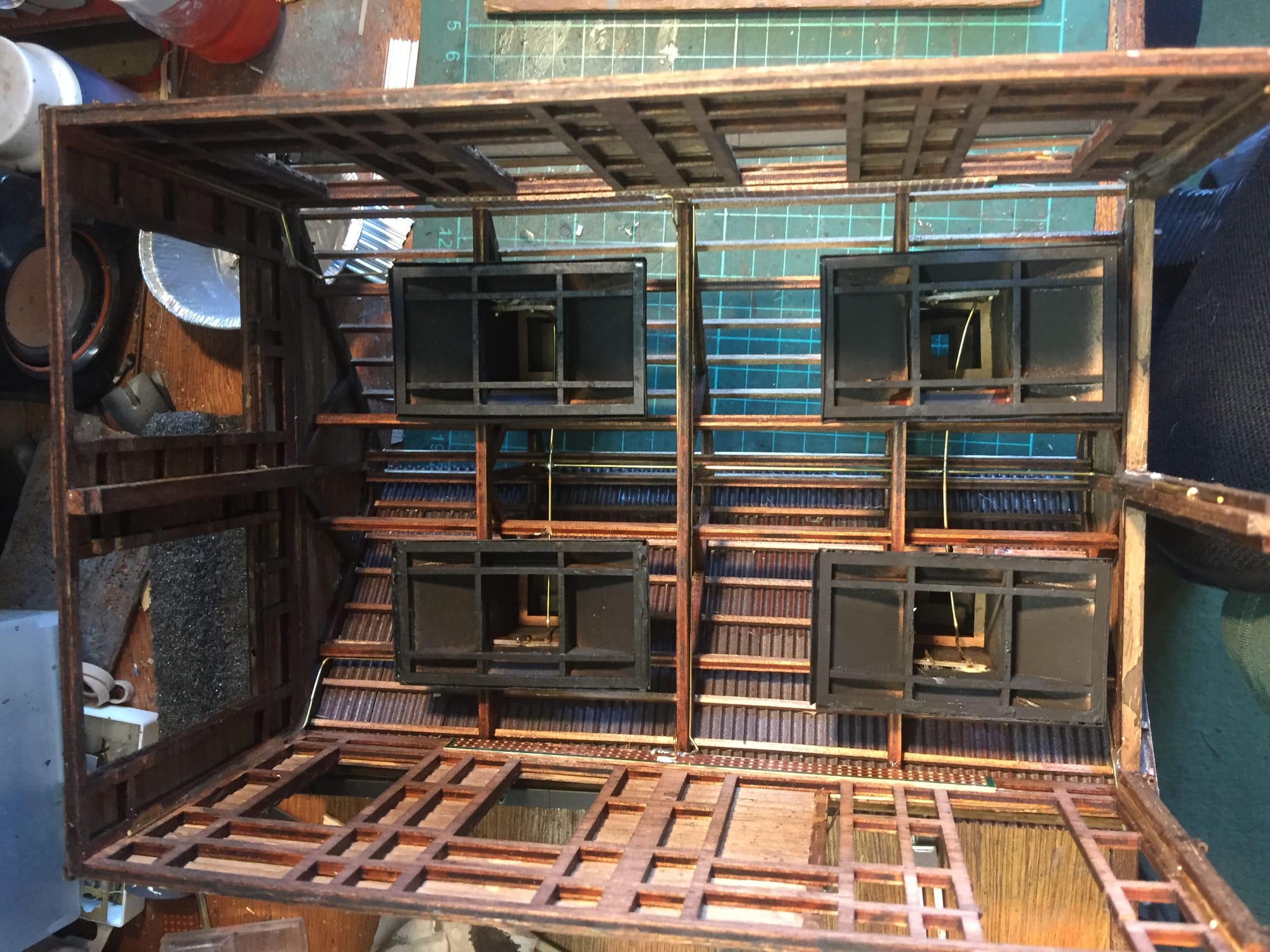

There are a number of smaller buildings, 2 offices and the body of a passenger brake from the 422 models range.

The grounded van & coach bodies are rejected 3d prints from a manin models 'scrap' box.

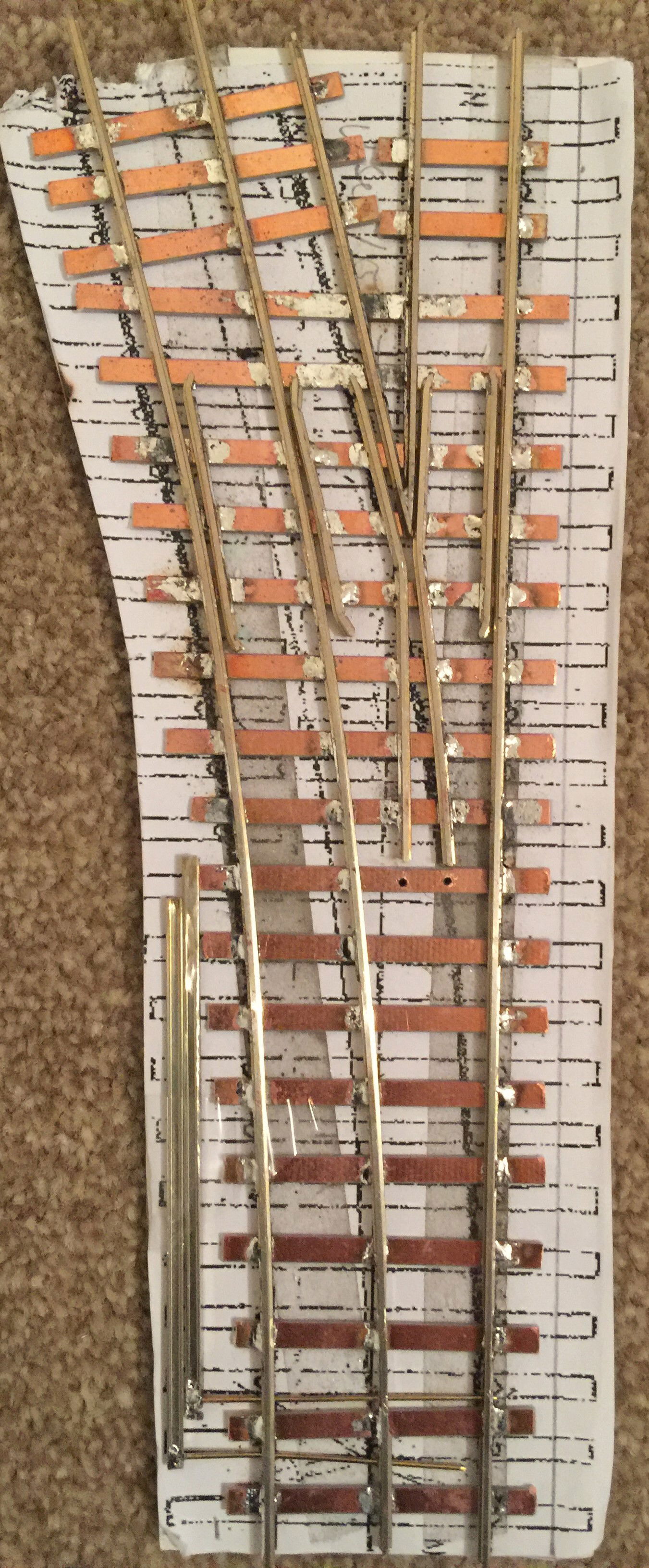

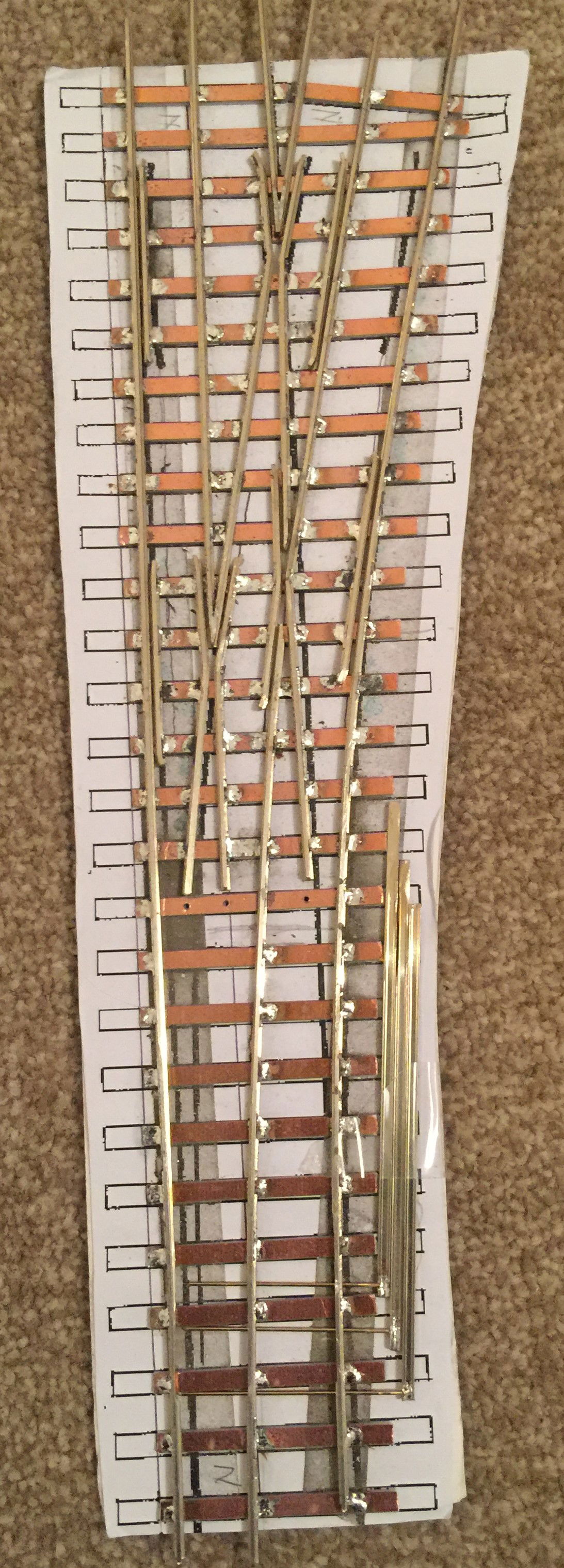

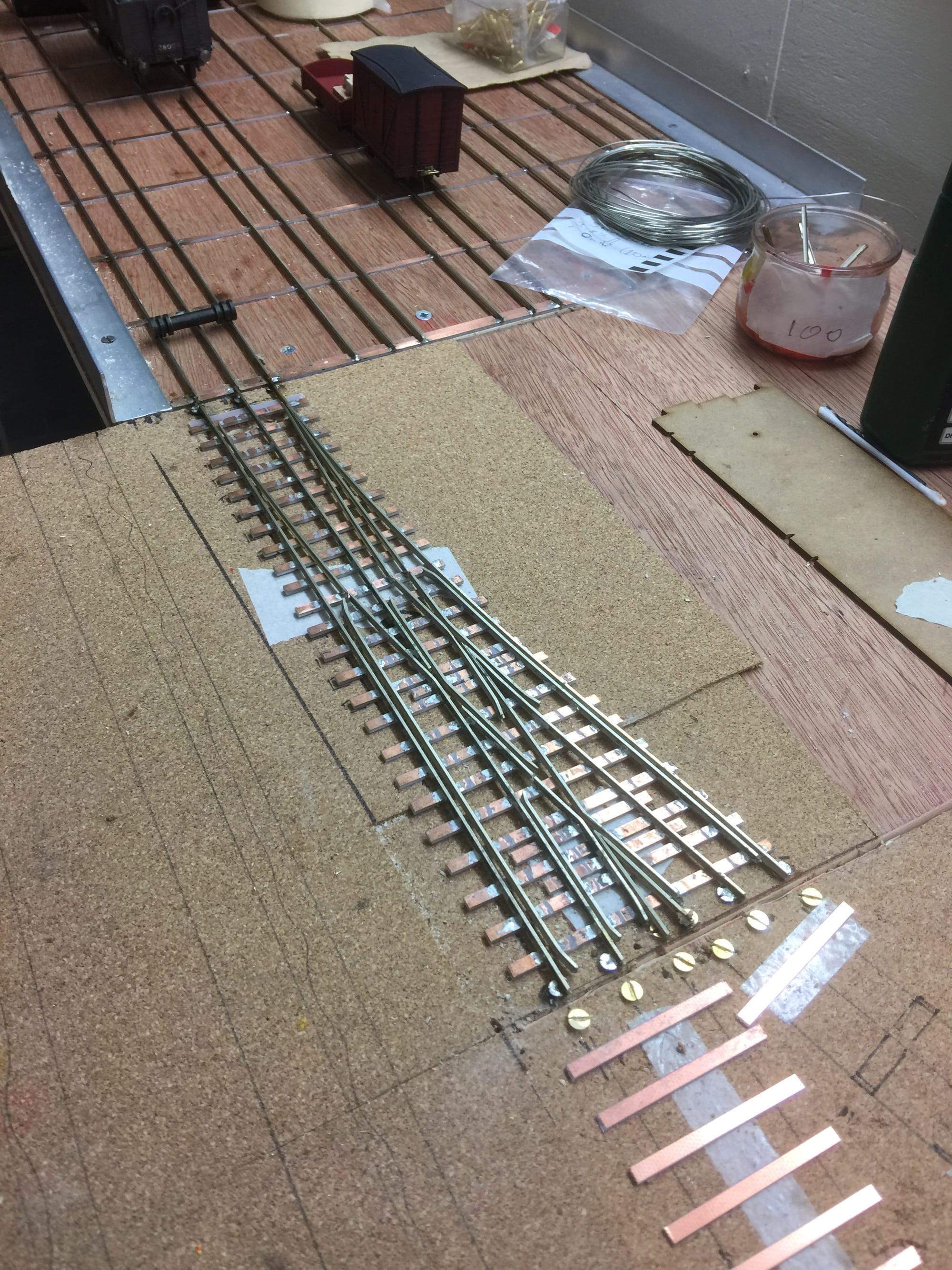

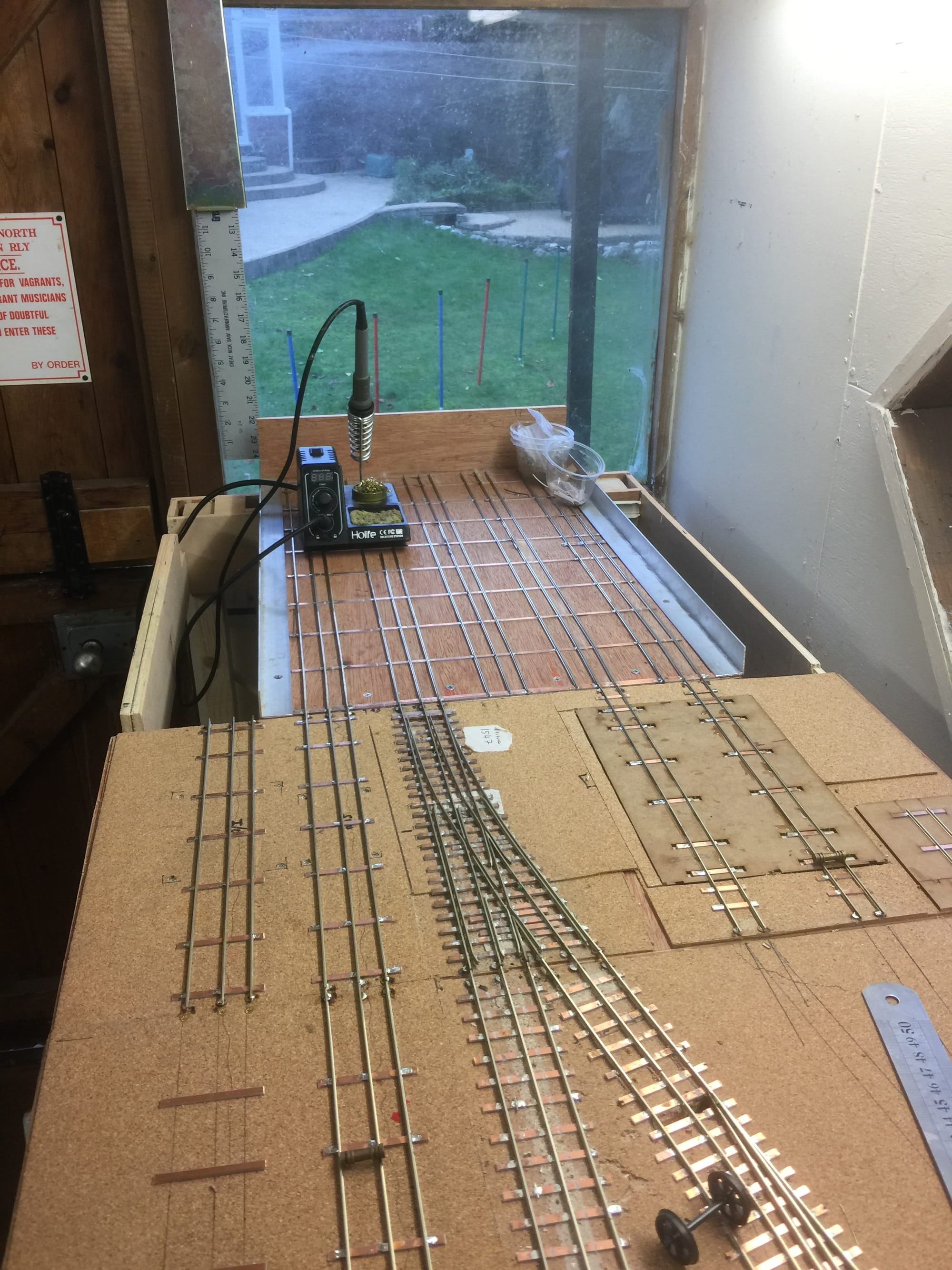

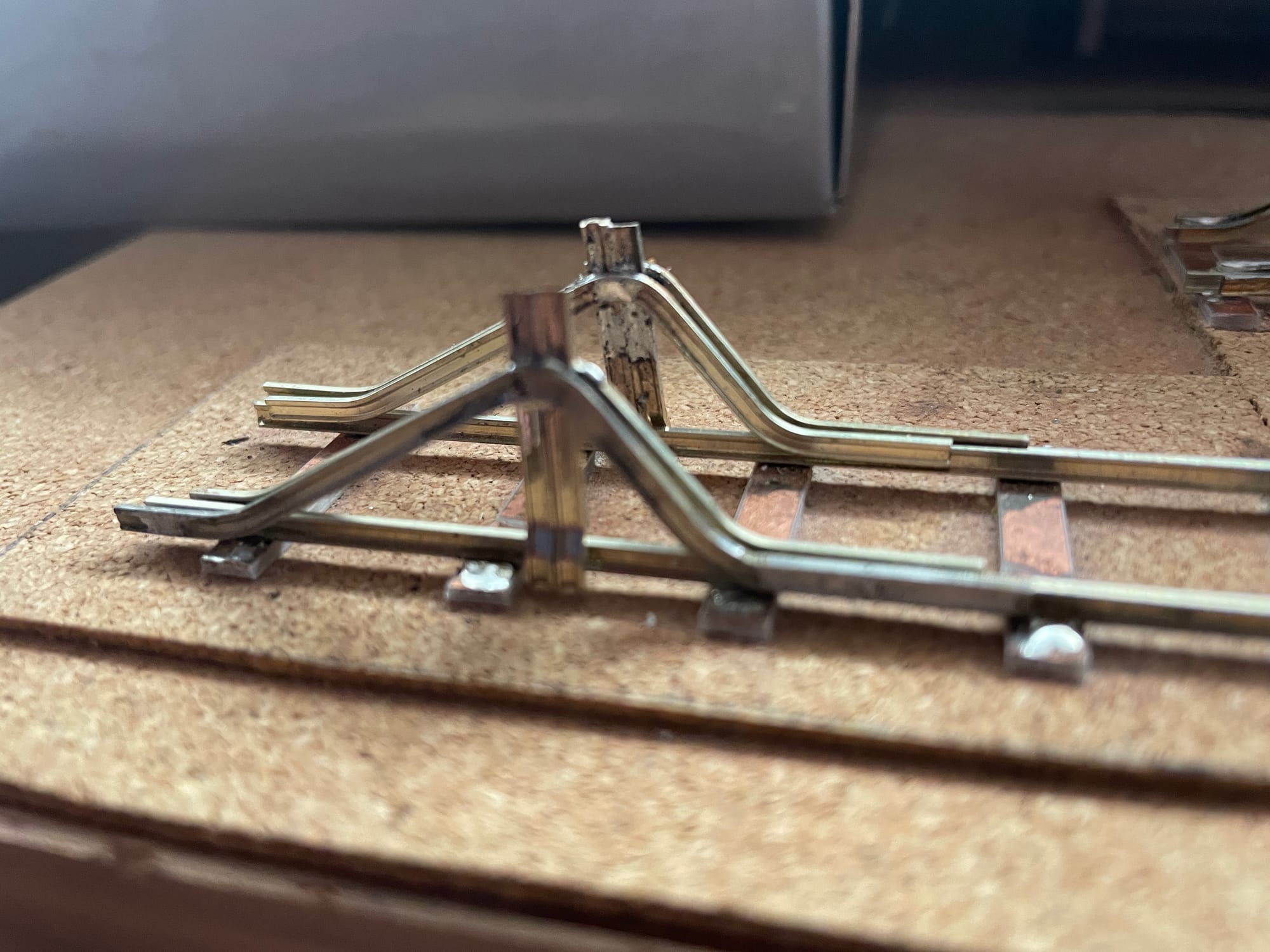

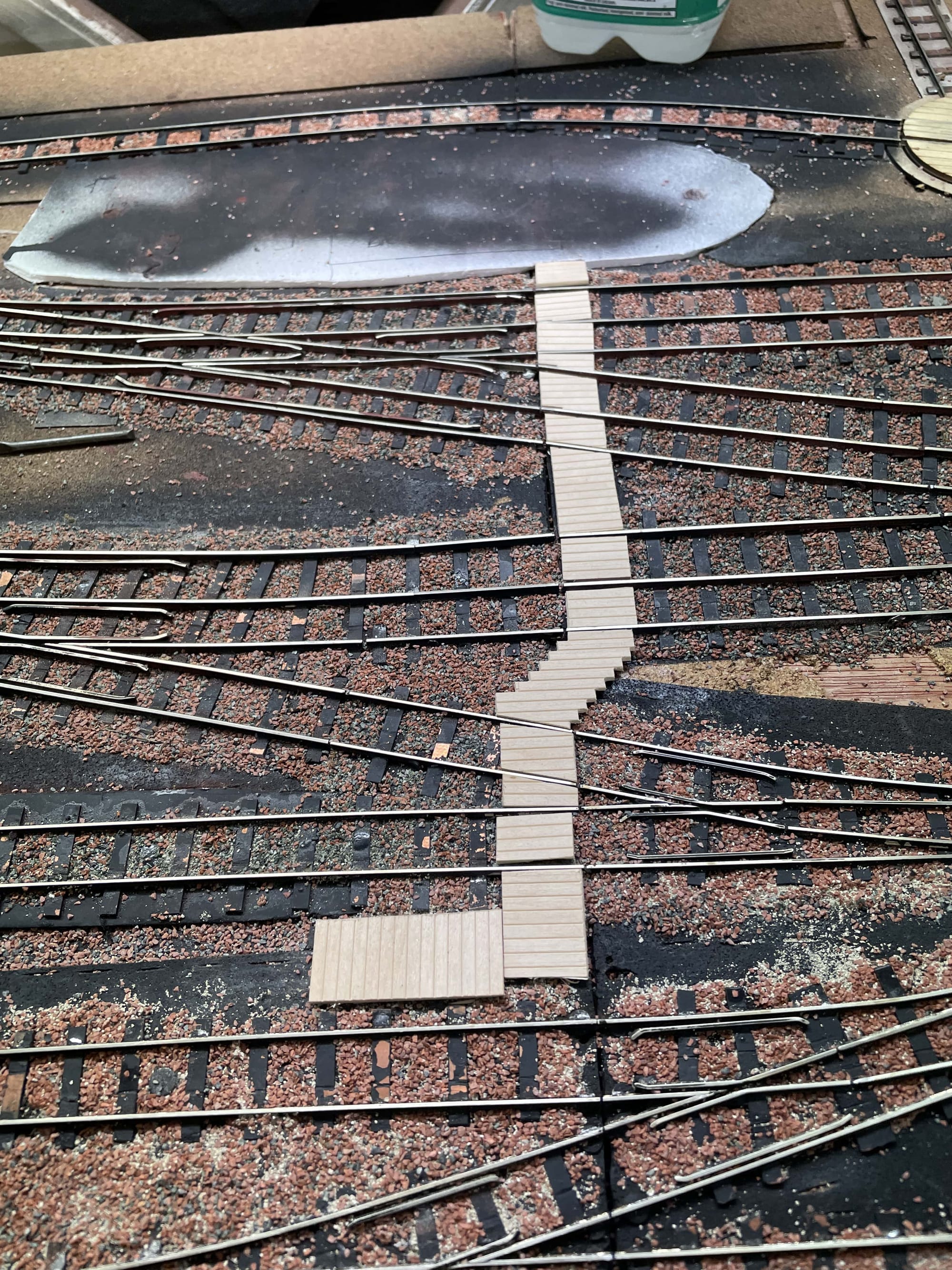

So all trackwork is handbuilt using soldred construction on copper clad sleepers. Code 100 rail has been used on the Dual gauge to represent a light 60LBS rail. The narrow gauge uses code 83 at the back and code 75 at the front. Why 2 different codes for the narrow gauge ? Well I had some code 83 left from a previous project and it matched the wagon turntable. The code 75 was the new purchase.

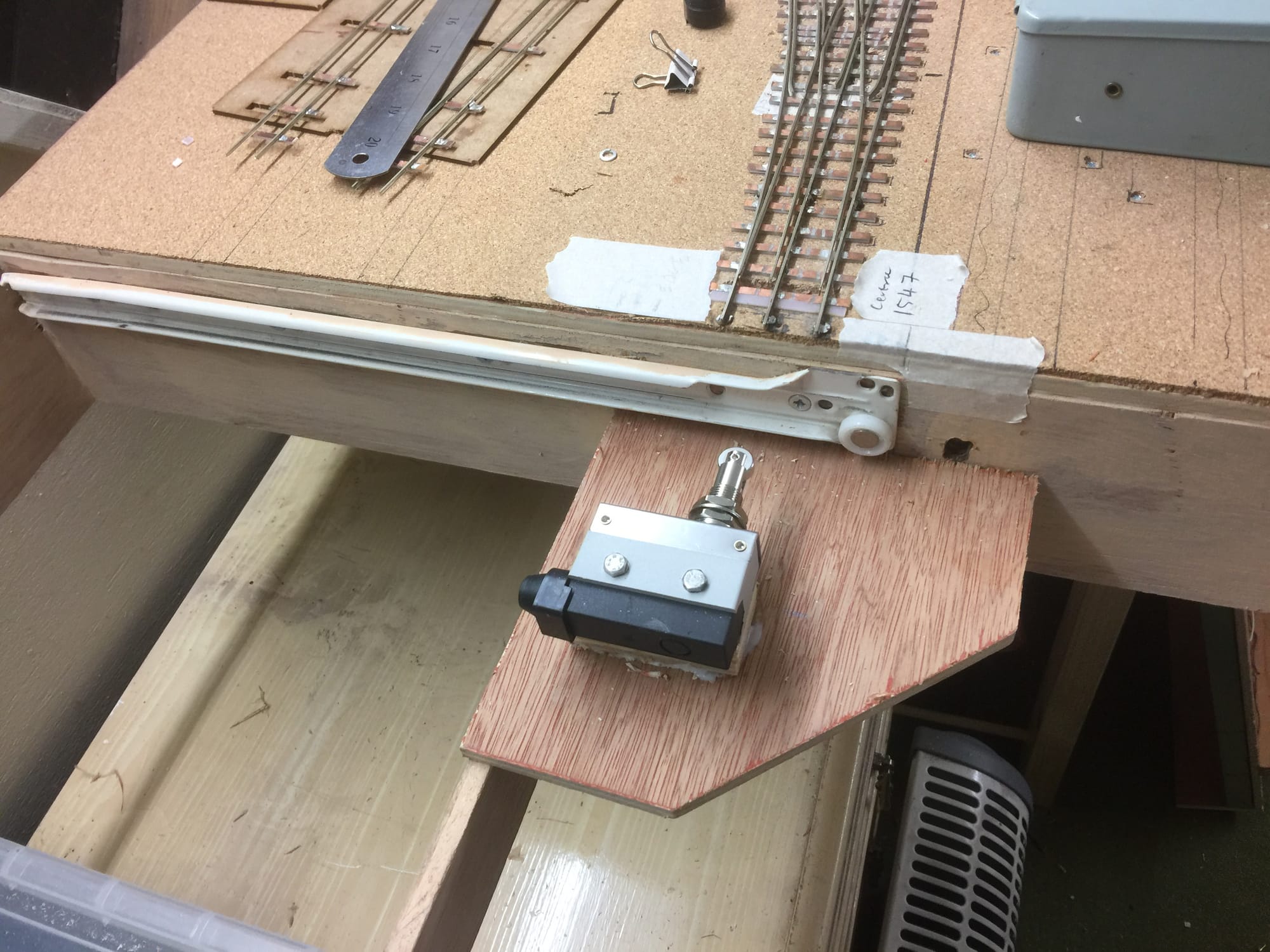

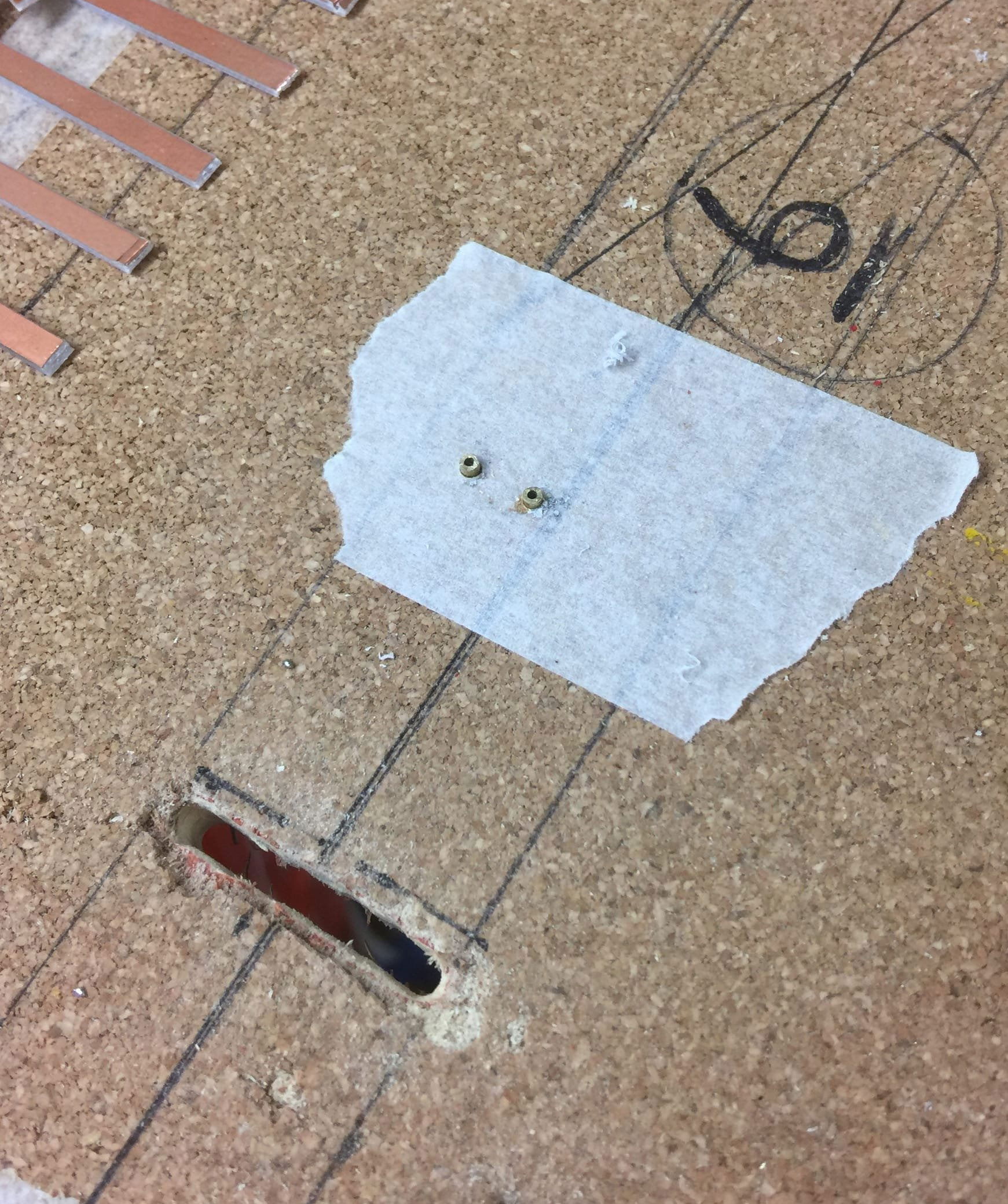

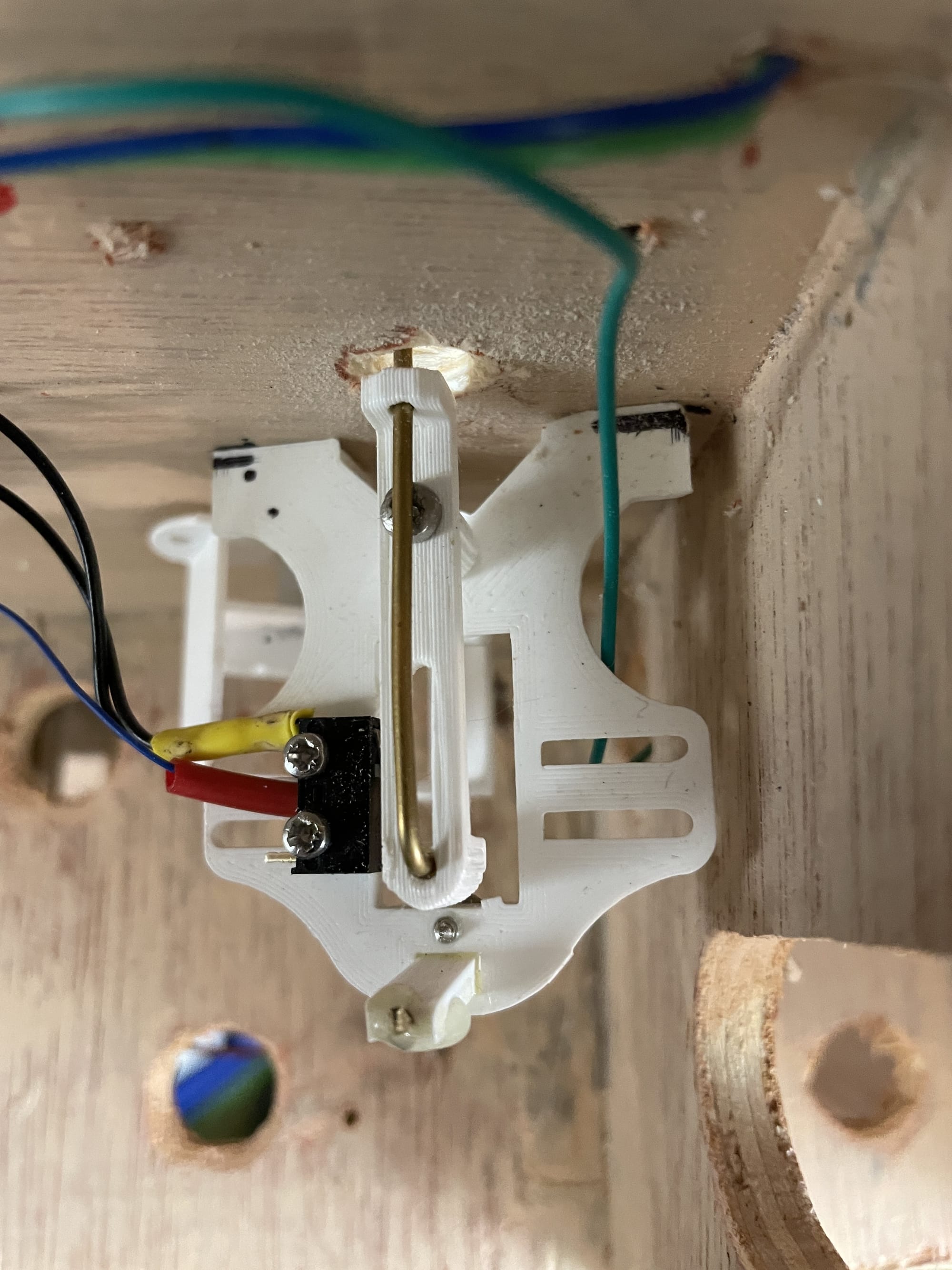

Points are operated by servo's using MERG servo control boards. The blades are lose heal, and given the tight radius this is prototypical. Each point blade has 0.9mm brass wire at the heal forming the pivot. 1mm brass tube is inset into the baseboards to act as the bearing.

A 0.7 mm dropper at the toe of each blade passes through the baseboard into a terminal block which is in turn connected to the servo.

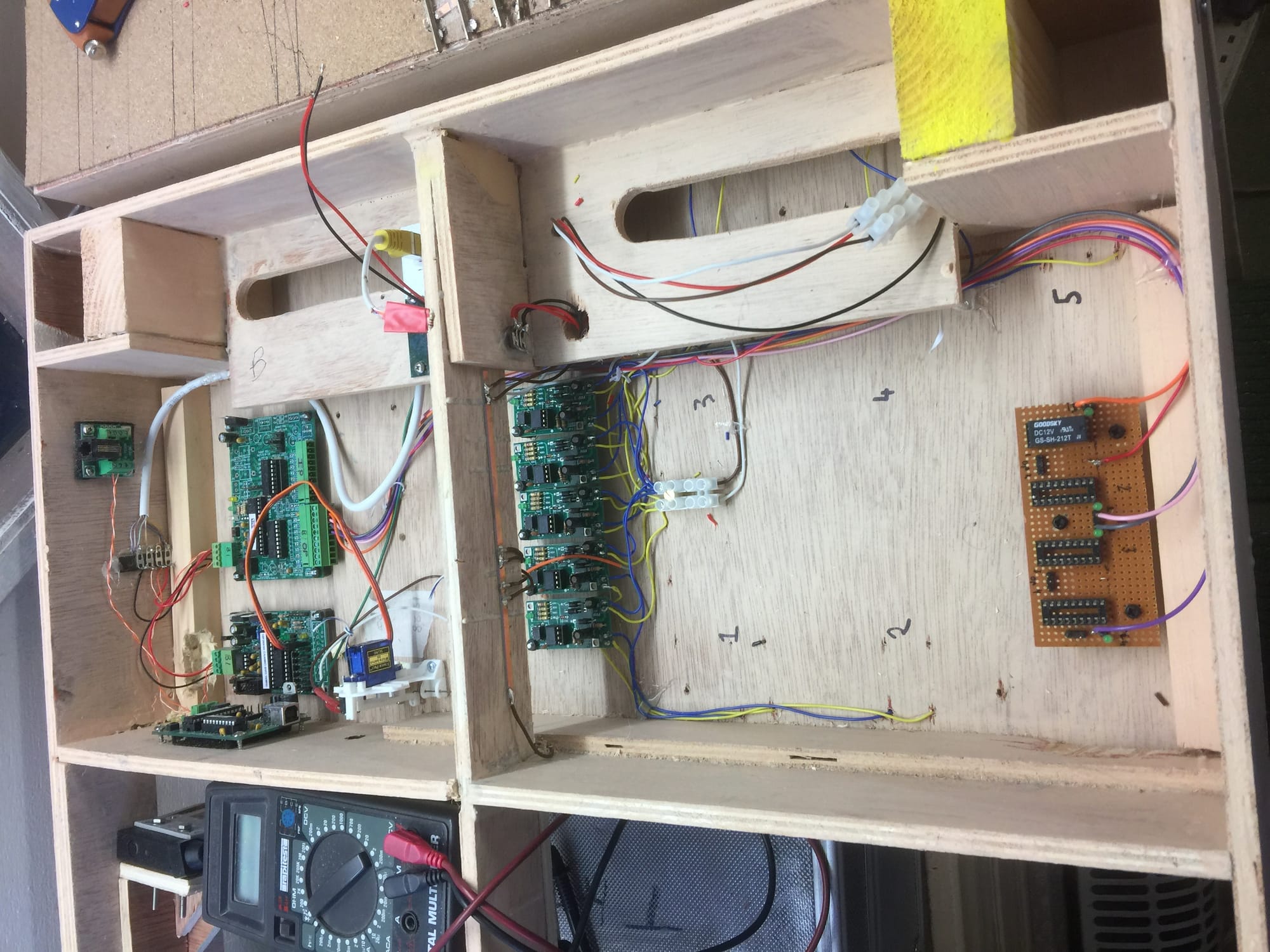

Electronics

Jubillee works uses MRG https://www.merg.org.uk/ cbus for control of points and accessories and the MERG DCC command station / booster. CBUS allows control modules throughout the layout to communicate over 2 wires minimising connections between base boards. On Jubilee works the DCC is plit into 2 zones so across each baseboard join there are 10 wires.

| DCC zone 1 - Dual gauge | 2 | 12V DC 1 - Control boards | 2 |

| DCC zone 2 - Narrow gauge | 2 | 12V DC 2 - Servo's and lighting | 2 |

| Cbus | 2 |

However between the control pannel and the layout just 4 wires 12vDC 1 and CBUS. The DCC command station (MERG kit 91a) feeds a boooster (Merg kit 59) configured for 5 Amp output. Each zone is fed via a district cut out module (Merg kit 57) and there are 2 throttles (Merg kit 92)

With the CBUS if had known when I started what I now understand of its capabilities I would have done things a little differently. Each of the 3 baseboards have a canmio - svo for the servo's, 2 for 1 of the boards, (MERG kit 98) and a canviout (MERG kit 11) providing inputs from the TOTI's and outputs for lighting / smoke units etc.

Train on track indication (TOTI) uses 3 methods.

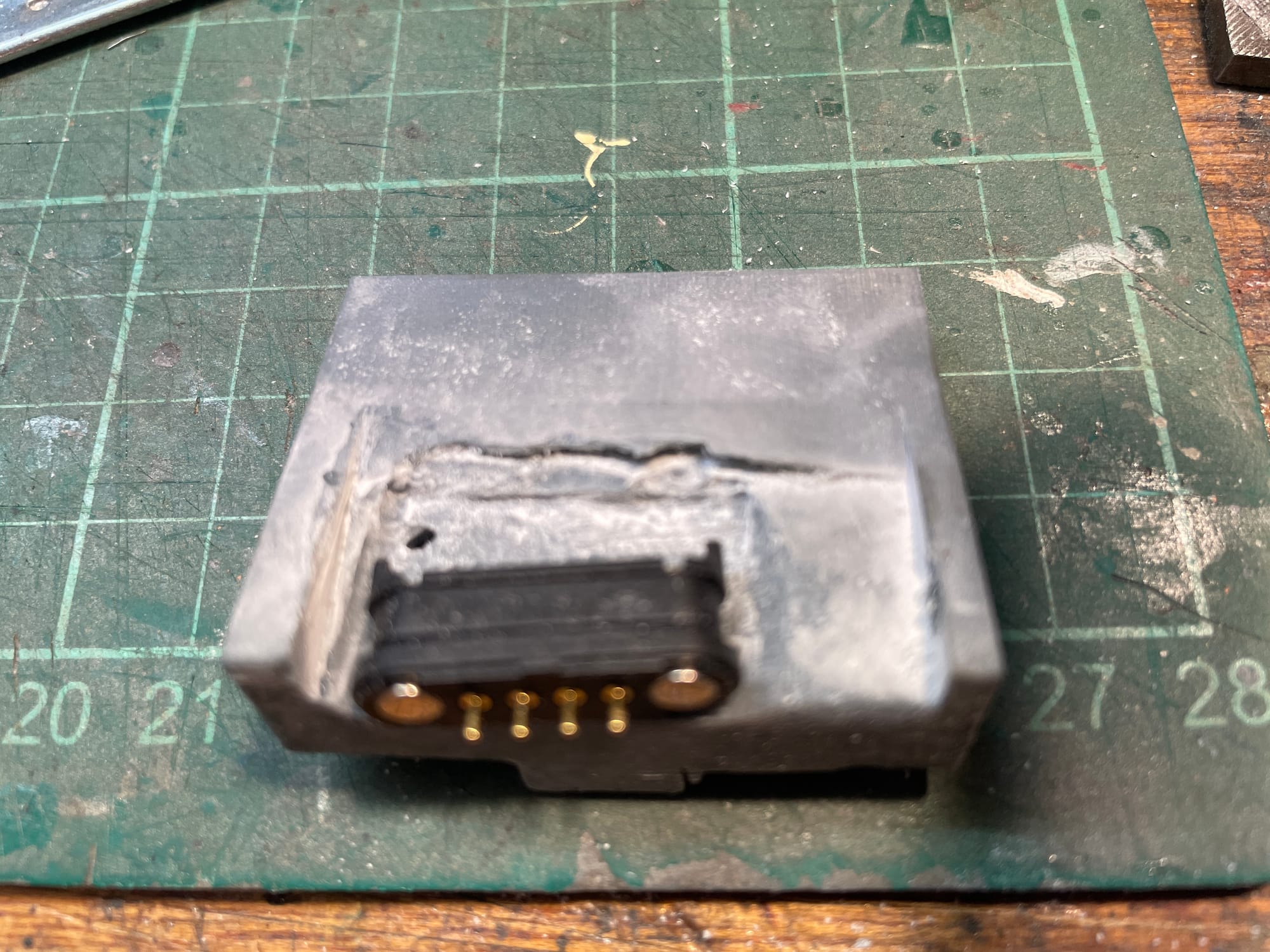

In the engine sheds the MERG PMK7 is used outputting to the canvout. In the transfer shed where there is no motor present Infra red , dual hector units ( MERG kit 72A) are used for presence. I also need an indication of when the stock is pressed against the buffer and micro switches are used for this.

The control Panel uses the canpan (MERG kit 97) in fact 2 of them as it exceeds the 32 LED capacity of a single unit. All switching is momentary leaving the option of multiple panel's either physical or soft.

Exhibitions

Jubilee works is due to be at the following exhibitions:

Date | Event | Link |

| 14/02/26 | East Beds MRS | https://ebmrs.org/club-exhibition/ |

| 28/03/26 | Royston & District MRC | http://www.roystondmrc.co.uk/index.html |

| 25/04/26 | Narrow Gauge South | http://www.narrowgaugesouth.org.uk/wp/ |

| 03/27 | Chesham Mrc | https://www.chesham-mrc.co.uk/index.php |

Past Exhibitions

Date | Event | Link |

03/03/24 | Chesham MRC | https://www.chesham-mrc.co.uk/ |

20/04/24 | De Haviland MRS | http://dhmrs.co.uk/ |

11/05/24 | South West Herts MRS | https://www.southwesthertsmrs.org.uk |

08/06/24 | 7mm Narrow gauge Association | |

| 06/09/25 | Tad-Rail 2025 | https://www.tringmrc.co.uk/ |

| 25/10/25 | Narrow Gauge Now | https://www.narrowgaugenow.uk/ |

Contact

- United Kingdom

Jubilee Works is available for exhibitions in the South East of England.